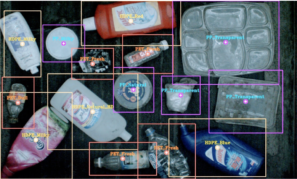

Technologies such as this waste classification by Ishitva Robotics’ NETRA Machine Vision has earned recognition

In a sector heavily dependent on unskilled informal workers, the use of sophisticated technology in recycling remains fairly limited. In this backdrop, Ahmedabad-based Ishitva Robotic Systems’ (IRS) success is notable. In August 2020, they were selected by The Alliance to End Plastic Waste and Plug and Play for an accelerator programme that supports startups on their innovations in ending plastic waste.

Established barely two years ago as India’s first automated waste-sorting systems provider, Ishitva’s growth trajectory indicates that Indian waste recyclers are slowly, but surely, opening up to the idea of using technology for better results. SolidWasteIndia spoke with Mr Sandip Singh, CEO – Ishitva Robotic Systems.

Q 1) Artificial Intelligence (AI)-powered air sorters are a relatively new concept in India, unlike the West. Could you please explain how your technology works?

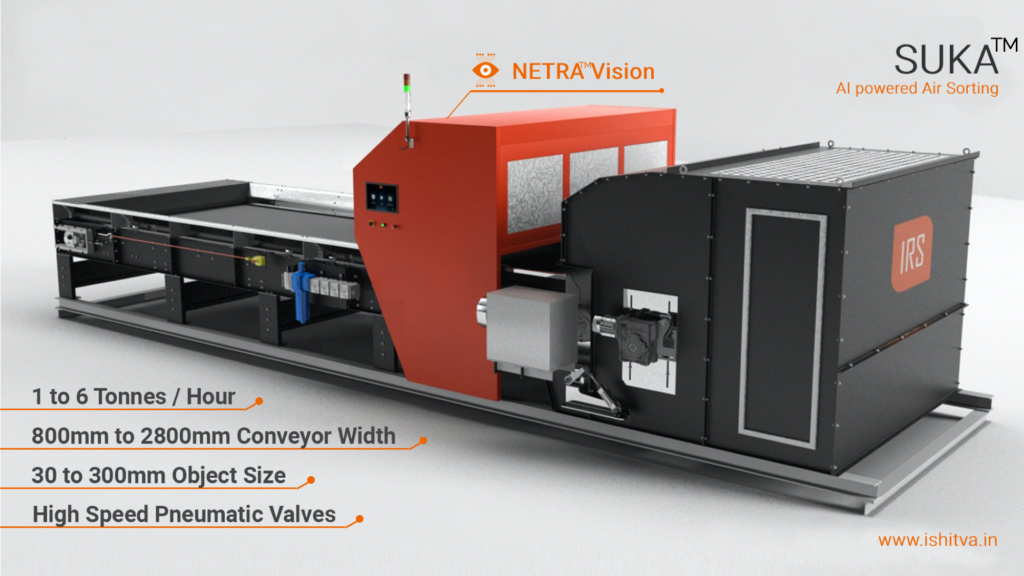

Over the years, air sorters have become integral in the efficient running of Material Recovery Facilities (MRFs). Various types of sensors and identification technologies are used with air sorters to recognize waste objects at a very high speed. Using this identification and recognition system, pneumatic shots are used to eject and separate the selected material from stream of material flowing on the conveyors.

Air sorting is necessary to handle scale as it has the ability to sort and recover large quantities of waste at a very high speed, enabling scalability and consistency. As we scale up our efforts to reduce landfills and recycle more waste under the Swachh Bharat Mission, re-thinking the technologies we use has become essential to the waste ecosystem in India.

Q 2) Tell us about your flagship product, Netra. What is unique about this system?

In Sanskrit/Hindi, NETRA means Vision / Eye. In our case, its value is way beyond that. We use the NETRATM in a unique way to identify and sort various types of waste streams.

Technologies like optical sorting systems that are commonly used in developed and high-income economies can prove very costly and economically unviable for developing countries. For one, these expensive technologies can only become viable at a large scale. Second, they depend upon the availability of good quality material for sorting.

The latter will remain a challenge for developing countries like India for some time. Thus, workable solutions which are cost effective at smaller scales and designed for decentralized waste management are needed. There is a need for economically viable material recognition processes for waste material sorting applications.

The Ishitva team led by our Founder Jitesh Dadlani took on this challenge and built an original optical sensor unit NETRATM which uses AI and machine vision to recognize the objects on a high-speed conveyor. It has processed and trained on millions of waste classifier images and continues to learn and get better every day.

Q 3) How does AI-based sorting compare to other sorting technologies currently practiced in India?

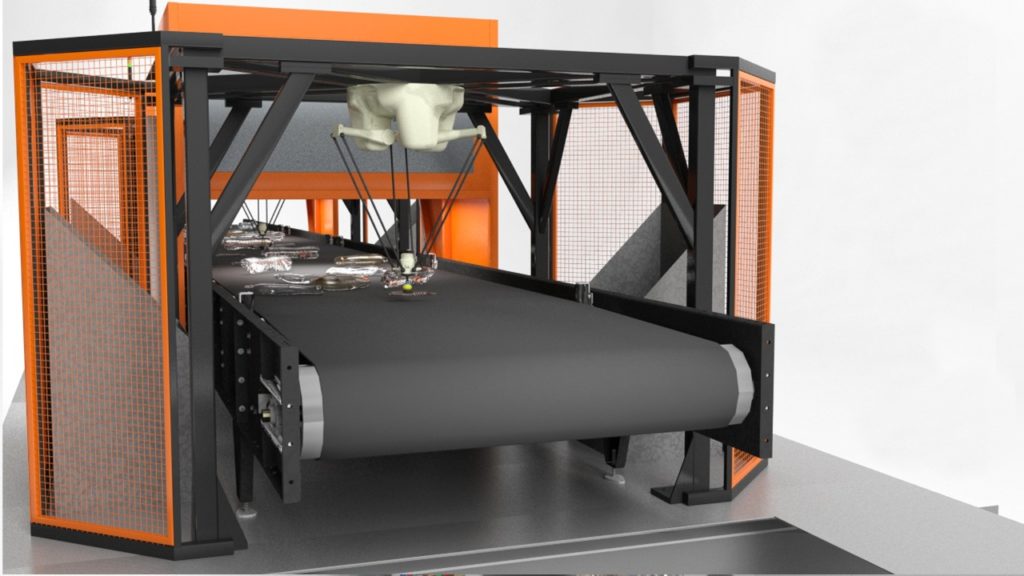

We are proud to be the first company to develop AI-powered sorting technologies in India and introduce these to the waste sector in India. We have created a full range of solutions including SUKATM (AI-powered Air Sorter), YUTATM(AI-powered Robotic Sorter), and SANJIVANITM (Fully Automated Sorting Solutions).

There are significant cost advantages of using AI against conventional sensor-based methods. One, it has the ability to capture and utilize the sorting data for numerous other business applications. Two, we also provide an option for ERP integration with inventory mapping, sales predictions etc. We expect to be the catalyst for technological transformation in the waste and recycling industry.

Q 4) What is the benefit of using sophisticated air-sorting technologies as compared to the much-cheaper option of manual sorting, which is the norm in India?

Manual sorting of waste at MRFs has its limitations. For instance, hiring and retaining skilled labor is difficult. There is also a reduced ability to identify the waste and segregate at scale. This directly impacts the consistency and profitability of manual segregation. Also, manual sorting is not cheap.

Contrary to common belief, sorting of dry waste is a complicated task apart from being dirty, dull and dangerous. The risks, associated with human sorting of waste, have further increased due to Covid 19.

The current market is also very focused on positive climate action. The scale at which it is required will need huge infrastructure creation in developing countries for management of waste and its recovery. Due to these reasons, both quality and quantity of sorting are often compromised and therefore, become the real bottleneck in the creation of circular value chain.

Through our technology, we can build systems which eliminate the requirement for multi-level sorting and achieve immediate results. Our automation solutions have the ability to reduce the cost of sorting to one-third of current levels depending on applications. They enhance the speed of sorting along with superior levels of purity as compared to human sorting.

Q 5) How adaptable is AI-based technology to meet multiple sorting needs associated with plastic waste?

AI makes it possible to handle multiple sorting needs, which is a challenge in manual sorting. We can identify polymer type, color, brand information etc., even if its dirty or out of shape. We have realized that our AI based solution is more accurate in real life scenarios for waste industries, as compared to other sensor-based solutions. Also, if our algorithm encounters a new waste item, it can be taught in a short time to achieve over ninety percent accuracy with little learning.

Q 6) What are some of the challenges you face in implementing your technology in India?

India is a very interesting market. Most of the unorganized players, are medium- and small-scale manually-run operations. They all suffer from similar problems but are unable to find adaptable solution. Sensing this gap, we are bringing automation to an industry which is a complete white space and therefore, has not seen any technology implementation before. We were encouraged to build end-to-end solutions which not only focus on a few key equipment but also come-up with something that achieves the sorting level which the people are used to and require.

Q 7) What is the overall price advantage of using AI in air-sorting?

There can never be a fixed price-tag on solutions to deal with such a massive environmental problem such as waste. Having said that, we tell all our customers this: the results of AI-powered sorting are remarkable, and the impact will be positive on the people, waste and profit. In most cases, we will be able to provide a payback within two years. Our SANJIVANITM System which sorts end to end is designed and positioned to provide payback under three years.

Mr Sandeep Singh is a panelist for the session “Leveraging Emerging Technologies for Waste Management” at the CII’s International Waste to Worth Conference on October 30. Ishitva Robotics will also be a part of the CII’s virtual exhibition from October 30 to November 15. Other major exhibitors include Blue Planet Environmental Solutions India Private Limited, Averda, Ecogreen Energy Pvt Ltd, The Shakti Plastic Industries, and IVL. Exhibitors from the Czech Republic, which is a partner country for the event include Enress s.r.o., FLORIUM s.r.o, H2O Group a.s, IBCSD LAB Ltd., LOGeco s.r.o and Stabilplastik spol. s r.o.

The CII’s International Conference on Waste to Worth is being organized by the Technology Development Board, GoI and supported by Swachh Bharat Mission, Ministry of Housing and Urban Affair, GoI. Register free for the CII conference and exhibition here.