The last session of the CII’s Waste to Worth Conference on November 17, titled ‘Untapped Potential – Challenges and Opportunities in Integrated/ Decentralized Waste Management in India focussed on WtE, decentralized biogas, bio-CNG, RDF and compost plants.

Cautioning attendees about the impact of linear economy on our climate, Ms Wilma Rodrigues, Founder – Saahas Zero Waste who moderated the session, said that the concept of Circular Economy (CE) itself is a work-in-progress and requires us to invest more effort. “People and the planet need to be put before profit. Saahas has seen through is decentralised models that 96 percent waste from landfills can be diverted and used as a resource thus closing the CE loop.”

Dr Shailja Gupta – Sr Advisor, Office of PSA, Government of India, in her special address, underlined the growing volumes of waste in India which need to treated on an urgent basis. “Livestock waste and multi-layered plastic waste are a big challenge for us. As per a Mc Kinsey report, $50-100 investment in WM can save $300 dollars in health costs. Waste management is not only the government’s problem. A behavioural change among citizens is essential to find out a sustainable solution.”

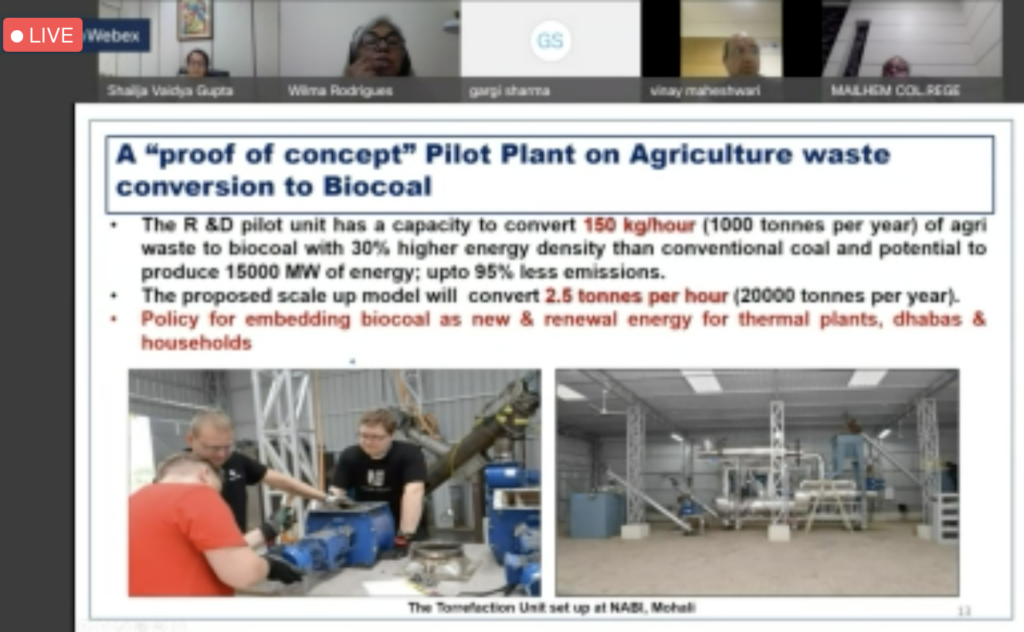

Noting that most of the urban drains in national capital are choked with waste, Dr Gupta listed initiatives by the government to pilot decentralised waste treatment technologies, such as the Waste to Wealth Technology Park in East Delhi, gasifiers by GD Environmental in Pune, Johkasou by Japanese firm Daiki Axis in Delhi. “”Decentralization is the key,” said Dr Gupta. “Under the PSA, we have been trying decentralised approaches to WM. For instance, Mohali’s National Agri-Food Biotechnology Institute (NABI) has tied up with Sweden’s BioENDEV to convert agricultural waste to bio-coal. Every project has challenges but we have to be persistent. These are old technologies and we are already too late in applying them.”

“The private sector’s involvement in sustainability is very important and the aspirations of a developing country population need to be taken into account in our vision for a circular economy, Dr Gupta felt. Developed Western nations make maximum use of the natural resources. It is their duty to provide us with technologies that are affordable and easy to use. No Indian technology which is available and can be taken to scale. R&D in India is severely lacking,” according to Dr Gupta.

Here are some of the other highlights of the session:

Col Suresh Rege – Executive Director, Mailhem Ikos

Col Rege shared Mailhem Ikos’ decades-old journey in organic waste management and its contribution to India’s vision of CE. More recently, the firm’s Integrated SWM plants are managing 600 TPD waste. Cost of WtE has shot up due to the ban on Chinese technology so we have to develop indigenous solutions. We convert plastic waste to granules as well as fuel through pyrolysis. The informal sector is a big help and they should be brought into the mainstream. We have 50 licensed waste-pickers who sort waste.

The technologies we use should be appropriate for Indian conditions. It’s available here but our fascination for foreign technology is not fruitful.

Mr Vinay Maheshwari, President – Corporate Projects & Environment Management, JBM Group

When asked about land availability and use for waste projects, Mr Maheshwari said the onus was on ULBs to provide adequate land to WM companies for efficient waste management services.

Mr Pankaj Tanwar – VP-Technical, Organic Recycling Systems (ORS)

ORS is running India’s largest biomethanization plant (400 TPD) in Solapur since a decade. “The compost produced by us is made from bio-degradable organic waste through our patented DRYAD process, which has low water requirement. It is free from foul odour, plastics, glasses and other non-biodegradable waste. Sold under the brand name of City Compost, SBESPL has been marketing, manufacturing and selling organic compost to the large scale chemical and fertilizer companies. It’s also sold directly to farmers across Maharashtra,” Mr Tanwar said.

“Given the prevailing poor source segregation levels in India, pre-treatment is very important to our technology. We eliminate the inorganic part and remove the toxics before processing the organic waste,” Mr Tanwar explained.

Mr V Sreenivas – Ecogreen Energy

Mr Sreenivas observed that source segregation remains the biggest challenge for the WM sector. To resolve this, a lot of traditional practices in household waste collection need to be replaced by new ideas. There are bylaws and strict enforcement is imperative. As a WM company, we serve as an important bridge between ULBs and the public to enforce the rules through IEC activities. In Lucknow, we are starting a new program in December to educate citizens about how to segregate waste at source. We will print educational material and distribute it at schools and train children to segregate waste so they can pass this learning to their parents at home.

To ensure WSS, we have provided segregated compartments in our vehicles. We have trained our drivers and helpers to segregate waste. The time has also come to customize technology to suit Indian conditions and the govt must financially support WM companies so they can function more effectively.

Mr Varun Boralkar, Head – Commercial, Geocycle India

Mr Boralkar shared Geocycle’s success in diverting 1.2 mn tonnes of waste from landfills.

The cement industry is among Geocycle’s biggest clients for RDF. “Pre-processing is one of our biggest focus areas today,” said Mr Boralkar. Regarding technology, developers and producers also need a large market like India. We need to incentivize technology developers and get the basics sorted. In the last few years, a lot of Indian manufacturers are coming forward and the technology landscape is changing. We are very conscious of the triple bottom line and are committed to a CE. We also need a policy reform on resource efficiency. The draft deals with Landfill Tax, Producers Pays Principle, which can further help reduce waste.”

Mr Sanjay Jalali – Group EVP & Operations Head, Blue Planet Environment Solutions

Mr Jalali gave an overview of Blue Planet’s waste portfolio in India and abroad. Blue Planet is a Singapore-based integrated waste management company that works through acquisition of companies involved in all aspects of WM.

“Being active in various geographies gives us an opportunity to learn and share our learnings across markets. We have 70+ decentralised units across India and 10 are being currently being commissioned. We are technology agnostic and look at technologies that meet the unique needs of each individual project. Our group companies adopt technologies that are best suited for their projects. We have successful service models in each location,” Mr Jalali said.

In terms of impact, Mr Jalali said that till date, 2.5 mn tonnes of waste has been processed through its various projects and 16,000 tonnes waste has been diverted from landfills by its group companies. We need to create symbiotic relationships that benefit all stakeholders.

Mr Marek Zaborowski, Team Leader at EU – India Technical Cooperation (Energy)

Mr Zaborowski felt price regulation and incentives are essential to make waste technologies succeed in India. “It took Poland nearly 20 years to set the fundamentals right and India too needs to set its policies straight. Regulatory changes in India are essential before technological solutions are enforced. Waste reduction is also extremely important and India must find its way to reduce waste per capita.”