The CII’s International Waste to Worth Conference saw a line-up of high profile speakers from the waste sector share their views on “Achieving a Circular Economy through 3R Techniques.”

The first session on “Glocal Models and Best Practices for Waste Management” saw the panelists showcase some of their companies’ best practices in India and abroad. Moderated by Mr Masood Mallick, Jt MD – Ramky Enviro Engineers Ltd, the panellists included Ms Wilma Rodrigues, CEO – Saahas Zero Waste, Mr Osten Ekengren of IVL Sweden, Mr Yashas Bhand, Director – Organic Recycling, Nicolas Maertens of Keppel Seghers, Michael Rada – Industry 5.0, and Rabih Jawad, Vice-President Operations, AVERDA, UK.

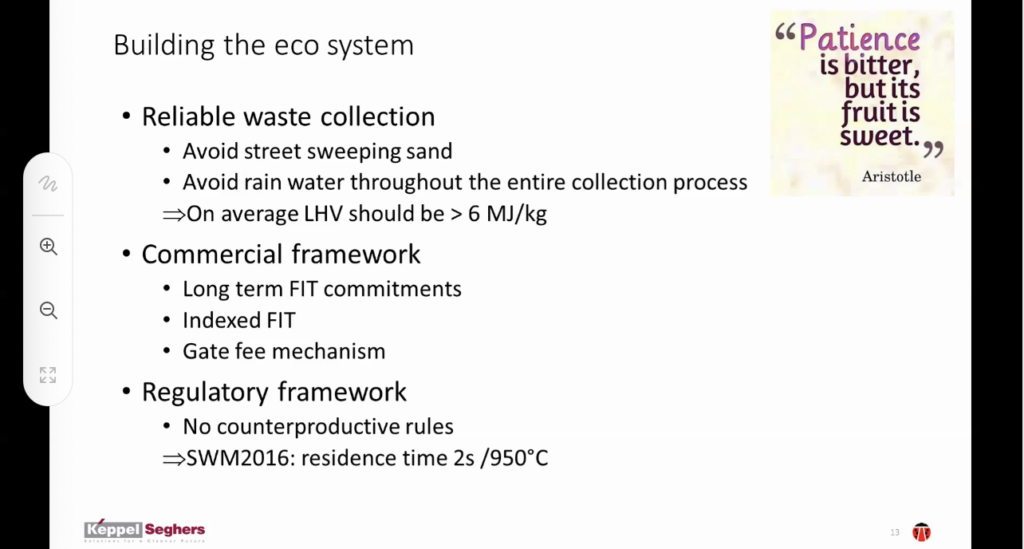

Mr Nicolas Maertens of Keppel Seghers was categorical in his assertion that the Indian Waste to Energy (WtE) sector is “digging its own grave” if it does not become more successful soon. “India should recognise that there are no shortcuts and we need to spend sufficient time and money to design and build WtE plants. The sector will become successful only if India is patient, understands the gaps and builds an ecosystem for successful WtE projects. This requires reliable waste collection, a proper regulatory and commercial framework wherein feed-in tariffs are indexed and a mechanism for gate fees is established. We also find that a lot of time is lost since BOOT contracts are not bankable.”

Responding to a question on whether large-scale WtE projects are suited to Indian conditions, Mr Maertens said that India has very large cities which can invest in WtE plants. “India has a lot to learn from China which has been successful in building a large WTE portfolio. They have built large plants to enjoy economies of scale and import critical items and components for these plants. They also work with experienced design engineers and invest in good O&M skills.”

Mr Yashas Bhand, Director – Organic Recycling, spoke about the essential ingredients required to make waste technologies successful in India. “Indian waste is diverse and area-specific. There is a need for standardization of waste technologies by organizations wherein definite performance guarantees can be put forth. Integrated solid waste management models are essential wherein decentralised processing plants are available for the inorganic fraction and centralised facilities or MRFs treat the recyclables. It is very important that the right fraction of the waste gets treated with the right kind of technology so that the process of the project development is financially and technically feasible.” Mr Bhand continued, “One of the challenges that we face as technology providers or project developers is putting forward the right technology due to data challenges. The government is pushing ahead with a lot of schemes for research and development in waste technology but one gap is the inavailability of data. Waste composition changes every season and India needs to create data centers so that we can plan our technology better.”

Mr Osten Ekengren of IVL Sweden elaborated on how the zero waste city model is being implemented in his country and can be replicated in other parts of the world. “The problem is that different authorities are responsible for different urban services. Thus, finding holistic solutions becomes complex. However, one must remember that a problem in one area can become a solution in another area.” Highlighting the value of waste incineration, Mr Ekengren said, “In India, people are afraid of incineration. Also, WtE plants only produce electricity, which is only one-third of the total energy content. The waste water that is released in the process is under-utilized and can become a valuable resource.”

Michael Rada spoke about Industry 5.0, a concept of waste prevention based on the principles of systematic waste prevention and industrial upcycling. “Industry 5.0 promotes a news mindset in people and businesses – from wasteful to wasteless. It is delivering results without capital investment and based on transparency, profit sharing and efficiency,” said Mr Rada.

Mr Rabih Jawad spoke of Averda’s plans for Amritsar, which marks the UAE-based company’s entry into the Indian market. Mr Jawad informed that Averda’s aim is to deliver on the concession agreements and requirements as needed. “However, we recognise that we are taking over an operation which has been impacted by historical impediments. We are liaising on priorities with authorities on priorities to be delivered first.” When asked during the Q&A session about the reason they chose to enter a market which has not “matured” yet, Mr Jawad asserted that Averda’s focus is on emerging markets to help communities become more environmentally sustainable. “There are challenges but Averda has the experience and believes it can make a positive impact. At the macro-level, India requires specific solutions as does every other country, market and community.”

In his concluding remarks, Mr Mallick said that while from the O&M standpoint, things don’t quite work in India like they do in Europe, there is no one-size-fits-all approach. “For large cities in India, WtE is possible. However, it’s important to understand that WtE is a waste management technology – not power generation technology. Also, today’s technology is clean and non-polluting due to the stringent standards that exist and the fact that emissions are monitored online so there is transparency. India is adapting global technologies to make sure that it follows robust environmental controls. For example, if you look at new waste energy plants, about 50% of the footprint of the plant is dedicated to pollution control technologies.”